Principle and characteristics of MS, MC, MZ series scraper conveyor:

Scraper conveyor is a kind of continuous conveying equipment which transports dust, small particles and small pieces in the shell of closed and rectangular section with the help of moving scraper chain. Because the scraper chain is completely buried in the material, it is also called "buried scraper conveyor".

The material has the characteristics of internal friction and side pressure. When conveying horizontally, the material is pushed by the old-fashioned chain in the direction of movement, so that the material is squeezed. Due to its own weight, internal friction is generated between the materials. This internal friction ensures the stable state between the material layers. When it is greater than the external friction between the material and the groove wall, the material forms a continuous and integral material flow In vertical lifting, due to the arching property of the material, the material is pushed by the scraper chain in the moving direction, and the lateral pressure is generated in the material, forming the internal friction of the material. At the same time, the continuous feeding of the lower level section produces a pushing force on the upper material, forcing the material to the center. When these forces are greater than the external friction between the material and the grid wall and the weight of the material itself, the material will form a continuous and integral material flow and be lifted. Because of the vibration in the movement of the scraper chain, the material arch will sometimes be damaged and sometimes formed. Therefore, when the material is transported vertically, the material is relative to the chain There will be a lag phenomenon in the strip, which has a slight effect on the conveying efficiency and speed, but does not hinder the normal operation.

The structure of the buried scraper conveyor is simple. It can not only transport horizontally, but also incline and vertically. At the same time, it can be combined and arranged in series. It can add more materials and discharge more materials. The process layout is flexible. Because the shell is closed, it can significantly improve the work when transporting materials and prevent environmental pollution. Application and classification: This machine is widely used in chemical industry, machinery, metallurgy, light industry, food, medicine, transportation, water and electricity and other departments to transport dust, small particles and small pieces of materials.

Buried scraper conveyor can be divided into general type and non general type, non general type can be: high temperature resistant type, corrosion resistant type, wear-resistant type, all gas sealed type and explosion-proof type and other special models, this type needs to be designed and produced separately through negotiation with the manufacturer.

General buried scraper conveyor is divided into: MS - horizontal buried scraper conveyor; MC - vertical buried scraper conveyor: MZ - Z buried scraper conveyor. There are three types and twelve specifications commonly used;

The general buried scraper conveyor has the following requirements for the transported materials

(1) Material capacity: r = 0.2-1.8 T / m.

(2) Temperature: material temperature T ≤ 120 ℃

(3) Moisture content: for general materials, it is not allowed to make materials not easy to loose after kneading by hand

The increase of moisture content will increase the adhesion and give the material, can not make the material seriously adhere to the scraper.

Main technical parameters and outline drawing of MS, MC, MZ series buried scraper conveyor

MS series buried scraper conveyor

Horizontal buried scraper conveyor can be divided into common type and large inclination type. The installation inclination of common type is

The installation angle of the large tilt type is 15 ﹤ a ﹤ 30.

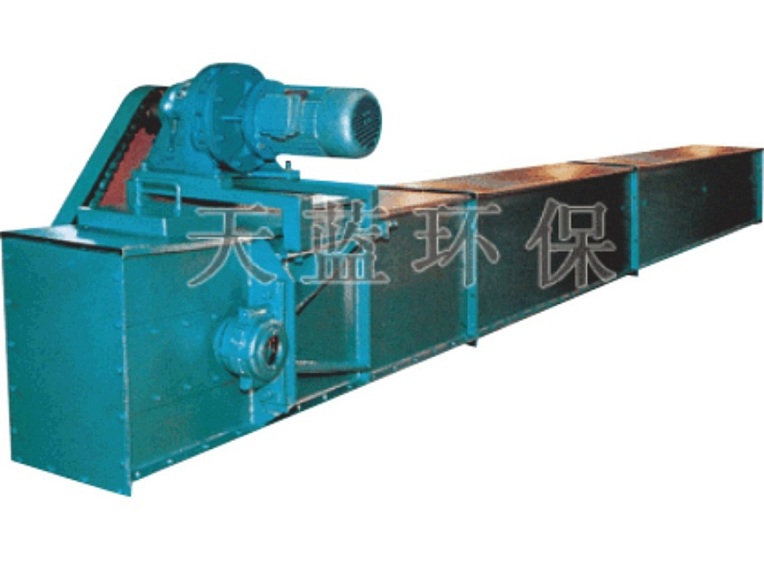

Schematic diagram of MS scraper conveyor:

Main technical parameters of MS scraper conveyor: